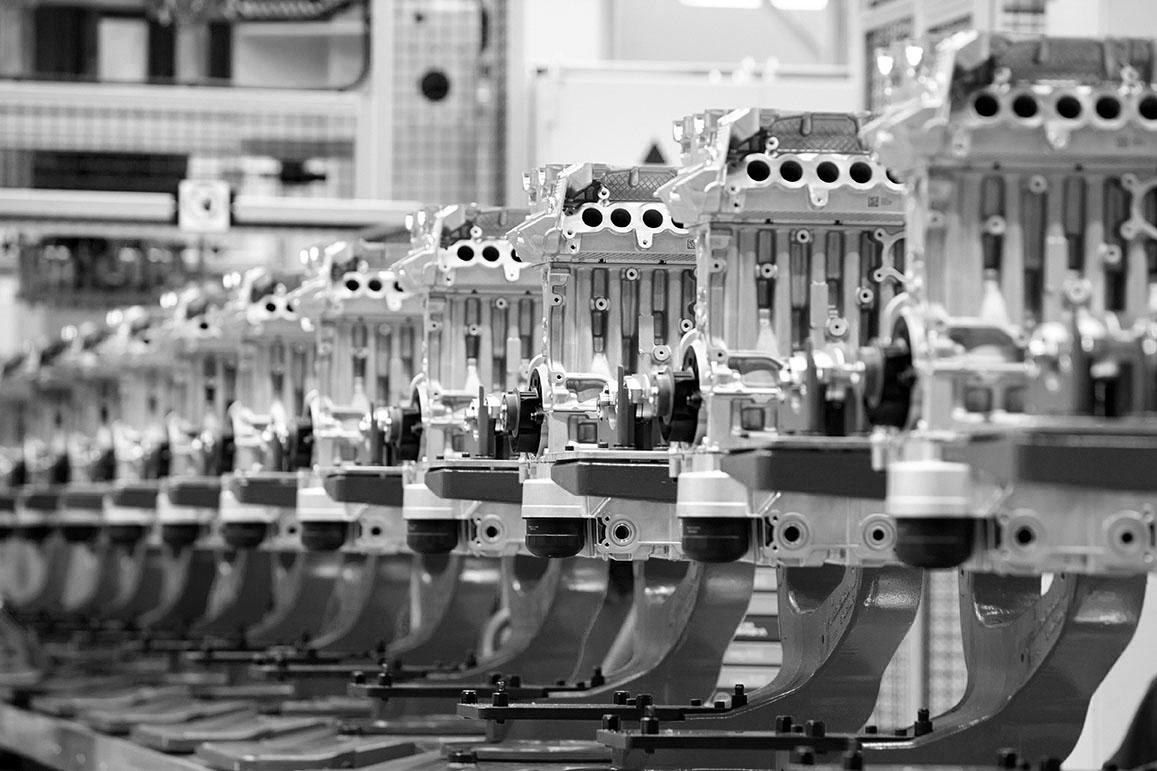

Industry 4.0, also known as the fourth industrial revolution, is a term that describes a new era of automation and data-driven processes in the manufacturing industry. One of the key technologies that plays a role in this is Manufacturing Execution Systems (MES).

MES is a computer-based system used to collect, store, and analyze data from various parts of a manufacturing process. It helps to increase efficiency, reduce costs, and improve the quality of products.

In Industry 4.0, MES is an important tool for creating a comprehensive overview of the manufacturing process. It helps to collect data from various sources such as machines, sensors, and facilities and provides a real-time view of the manufacturing process. This enables companies to quickly identify and solve problems that may arise.

MES is also important for creating a link between different parts of the manufacturing process. It helps to integrate data from various sources and enables companies to make more informed decisions.

Another important aspect of MES is its ability to handle complex production processes. It helps to automate and optimize processes such as planning, scheduling, and execution, enabling companies to reduce lead times and increase efficiency.

Overall, MES is an important technology for companies looking to implement Industry 4.0. It helps to create a comprehensive view of the manufacturing process, enables the integration of data from various sources, and helps to automate and optimize processes. This gives companies increased flexibility and competitiveness.